Introduction

In the vast landscape of paper manufacturing, the heart of the process lies in the details of the machinery involved. One pivotal component that significantly influences the quality and efficiency of paper production is the headbox paper machine. Let’s delve into the diverse world of headboxes, exploring their types, functions, and the critical role they play in the paper-making journey.

What is a Headbox?

A headbox is the most essential component in the papermaking process and is purely responsible for distributing a uniform and controlled flow of pulp onto the forming fabric or wire to create a desired paper sheet. It is a complex system with various components working harmoniously to ensure a uniform and controlled flow of pulp onto the paper machine. The design and operation of the headbox paper machine are purely responsible for the quality and properties of the final paper product.

There are many types of headbox in paper machine used in paper mills. In this blog discussion, we will acquaint ourselves with some commonly used types of headboxes in paper machines employed by paper mills. Each type serves a unique purpose in the paper manufacturing process, bringing with it specific advantages. Additionally, these headboxes find application in paper machines operating at different speed levels.

A. Open Headbox:

The opening headbox is a design specifically tailored for low-speed paper machines. It controls the speed of the inlet wire paper stream, offering an enhanced rectification effect for the open headbox pulp. As the paper machine speed increases to more than 250m/min, the open headbox presents challenges. Its volume and height become larger and more complex, limiting its adaptability to further speed increments.

· In an open headbox, the pulp flows freely over a distribution lip or a series of lips.

· The flow is not confined, allowing the pulp to spread and form a thin sheet as it exits the headbox.

· Open headboxes are generally used in the production of board and packaging grades of paper.

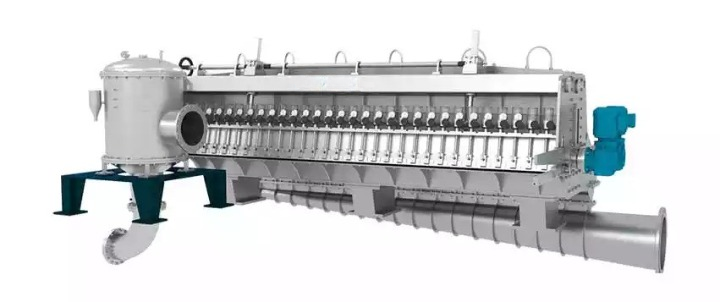

B. Closed Headbox:

Ideal for paper machines with speeds ranging more than open headbox, the closed headbox is employed in long-wire or hybrid network configurations. Adjusting the air cushion pressure allows for seamless speed changes in the paper web flow. This results in a flexible operation, convenient adjustments, and an overall effective performance.

a. Closed headboxes are designed with a slice or an adjustable opening through which the pulp is released onto the forming fabric.

b. The closed design provides better control over the pulp flow and allows for precise adjustments to achieve uniform sheet formation.

c. Closed headboxes are commonly used in the production of fine papers, printing papers, and other high-quality paper grades.

Within these two main types, there are further variations and features that manufacturers may incorporate to meet specific requirements. Some headboxes have advanced technologies, such as dilution control systems, turbulence control, and profiling capabilities, to enhance the papermaking process and improve sheet formation.

Here are some of the types of Closed Headbox paper machine:

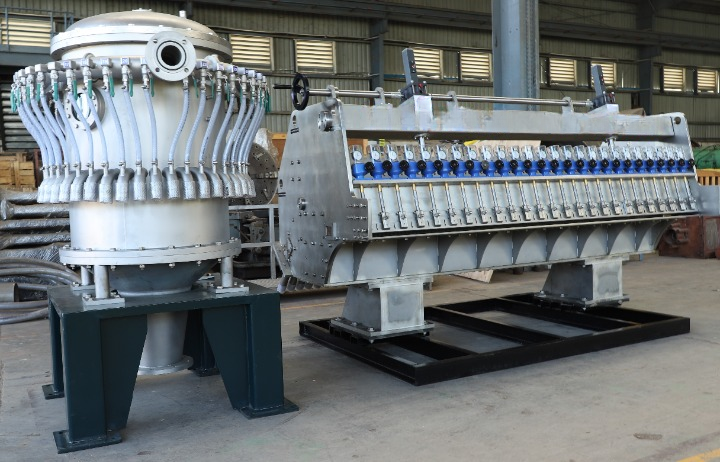

1. Hydraulic Headbox:

Tailored for high-speed paper machines reaching up to 1200 m/min to 2200m/min, the hydraulic headbox excels in controlling the edge flow of directional distribution for fiber banners. It ensures a uniform lateral quantitative distribution and promotes a favorable fiber orientation distribution, contributing to optimal paper quality at elevated speeds.

Headbox is designed to achieve the optimal balance between high paper quality and low energy costs. Featuring two evenly positioned deflocculating rolls within the pressurized headbox, this innovative design enhances paper quality while simultaneously enabling significant energy savings for users. The incorporation of precise cross profiles of grammage (CD profile) ensures the maintenance of paper consistency, while careful management of fiber orientation further contributes to improved overall paper quality.

Hydraulic Headbox paper machine further can be classified as:

· Accujet High Turbulence Hydraulic Headbox with Central Distribution Tank (CDT)

· Accujet High Turbulence Hydraulic Headbox without CDT

As the name suggests, the hydraulic headbox working principle suggests the classification of with or without CDT.

2. Pressurized Headbox:

The Pressurized Headbox is designed to achieve the optimal balance between high paper quality and low energy costs. Featuring two evenly positioned deflocculating rolls within the pressurized headbox, this innovative design enhances paper quality while simultaneously enabling significant energy savings for users. The incorporation of precise cross profiles of grammage (CD profile) ensures the maintenance of paper consistency, while careful management of fiber orientation further contributes to improved overall paper quality.

The Pressurized Headbox can be classified into 2 types:

· Air Cushioned Pressurized Headbox with Pulses and Damping Tank (PDT)

· Air Cushioned Pressurized Headbox without Pulses and Damping Tank (PDT)

Internally, all surfaces that come in contact with the stock flow undergo a meticulous polishing process, promoting smooth and efficient operation. The headbox incorporates turbulence generators along with tube banks and nozzles to enhance operational efficiency and ensure excellent runnability. Motorized slice lips provide the flexibility to adjust the slice gap between lips, offering control over the output of stock flow. The finely tuned headbox design guarantees excellent stock dispersion, ultimately contributing to the best possible sheet formation during the papermaking process.

Conclusion

In conclusion, the types of headboxes in paper machines are diverse and nuanced, each contributing uniquely to the paper-making process. Choosing the right headbox is a decision that reverberates throughout the entire manufacturing journey, impacting the quality, efficiency, and sustainability of paper production.

FAQs

1. Are headboxes essential for all paper machines?

· Yes, headboxes play a crucial role in ensuring the even distribution of pulp, making them essential components for most paper machines.

2. When selecting a headbox, what factors should be considered?

· Factors such as the type of paper, quality requirements, and production speed are pivotal considerations in the selection of a headbox.

3. Can headboxes be upgraded to incorporate the latest technology?

· Yes, many headboxes can be upgraded to integrate the latest technological advancements, enhancing their efficiency and performance.

4. How often should headboxes undergo maintenance?

· Regular maintenance is key to the longevity of headboxes. Depending on usage, a scheduled maintenance routine should be established.

5. Are high-speed headboxes suitable for all paper types?

· High-speed headboxes are versatile but may be better suited for specific paper types. It’s crucial to match the headbox type with the paper production requirements.