Introduction

In the realm of pulp and paper processing, efficiency is paramount. Turbo Separator emerges as a game-changer, addressing the challenges posed by high trash and flake content. Turbo Separator is a screening device used in many industries where the screening of the recycling materials is required. One of the most important uses of the Turbo Separator is in the Pulp and Paper Industries.

This article delves into the applications, salient features, and the working principle of Turbo Separator that makes it an indispensable asset in the industry.

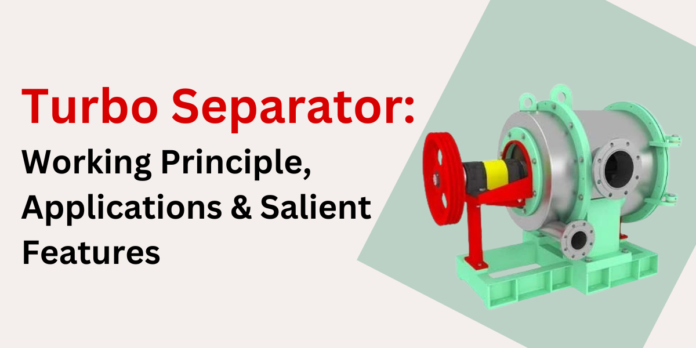

Turbo Separator

What is a Turbo Separator? The Turbo Separator is a cutting-edge disc screen, which has been meticulously crafted for coarse screening applications, particularly in the pulp strainers dealing with elevated levels of trash and flake content, such as recycled paper.

This innovative screening solution excels in handling pulp slurries loaded with high trash and flake content. It not only serves as a primary screen but also proves to be a valuable asset as a secondary screen when paired with a cylindrical screen in the initial stage of the screening process.

Key Features:

Enhanced De-flaking Potential: The Turbo Separator sets itself apart by offering a higher De-flaking potential, contributing to a more efficient and refined screening process.

Reliable Operation: Ensuring dependable and consistent performance, this disc screen guarantees reliable operation, meeting the demands of industrial processes with precision.

Contaminants Removal: A standout feature lies in its ability to remove contaminants, both light and heavy rejects, separately. This dual-action approach enhances the overall efficiency of the screening process, leaving you with a cleaner and more refined end product.

Working Principle

The working principle of the Turbo Separator capitalizes on centrifugal forces generated by rotating discs to effectively separate and remove contaminants from materials, making it a reliable and efficient solution for coarse screening applications in various industrial processes.

The working mechanism of the Turbo Separator involves the introduction of pulp stock into the inlet chamber through a tangential inlet. Within this inlet chamber, strategically positioned outlets work for both heavy rejects and light rejects. A screen, equipped with a rotor featuring multiple curved blades, separates the accept chamber from the inlet chamber, facilitating the screening process.

Here’s a breakdown of its working principle:

Material Feed:

The process begins with the introduction of the material to be screened. In the context of the Turbo Separator, this often involves feeding pulp slurries containing a substantial amount of trash and flake content through the tangential inlet.

Rotating Discs:

The heart of the Turbo Separator lies in its rotating disc assembly. As the material moves through the screening unit, these discs, set at specific angles, play a crucial role. The rotating motion of the discs facilitates the separation of different components within the material.

Centrifugal Forces:

The key to the Turbo Separator’s effectiveness lies in the application of centrifugal forces. As the material passes through the rotating discs, these forces come into play, causing the heavier contaminants, such as unwanted flakes and trash, to be propelled outward. Simultaneously, the cleaner material moves towards the center of the discs.

Dual Screening Action:

The Turbo Separator often functions as a primary screen for coarse screening tasks. However, it can also be employed as a secondary screen, working in tandem with other screening units. In this dual-screening setup, it further refines the material by removing additional contaminants, enhancing the overall screening efficiency.

Contaminant Discharge:

The separated contaminants are efficiently discharged from the system through the reject outlet. The design of the Turbo Separator allows for the removal of both light and heavy rejects separately, contributing to the production of a cleaner end product.

Higher De-flaking Potential:

A notable feature of the Turbo Separator is its higher de-flaking potential. This aspect ensures that not only are contaminants removed, but the screening process also aids in breaking down unwanted flakes, leading to a more refined output.

Applications: The Turbo Separator Uses

A turbo separator is a device used in various industries for the separation of materials based on their size, density, and other characteristics. Some of the common applications and turbo separator uses are:

- Waste Recycling

- Food Processing

- Mineral Processing

- Plastics and Rubber Industry

- Wood Processing

- Paper and Pulp Industry

- Textile Industry

- Environmental Applications

- Water Treatment

The use of turbo separators varies across industries, and their versatility makes them valuable in processes where material separation is required.

The Best Turbo Separator Manufacturers

Many industries use Turbo Separator as mentioned above. However, the most common use of the Turbo Separator is in the paper industry in India. There are several paper mill machinery manufacturers available worldwide, but very few happen to be providing good quality and can be a reliable partner for your paper machinery needs.

When choosing to get a turbo separator for your needs, you need to take a few factors into consideration and the manufacturer is one of them including the turbo separator price in India. Here is the list of the Turbo Separator manufacturers:

Conclusion:

The Turbo Separator emerges as a formidable player in the realm of pulp and paper processing. Its versatile applications in many industries coupled with salient features and an efficient working principle, make it an indispensable asset for industries aiming for top-tier efficiency and quality.