How High-Density Cleaner Machinery Improves Pulp Quality

In the realm of paper production, the quality of pulp utilized is paramount for the production of superior-grade papers. A multitude of processes, including pulping, refining, de-flaking, deinking, cleaning, and more, are integral to ensuring the quality of the final paper product.

Whether engaged in recycled or virgin paper production, both necessitate the pulping process, utilizing raw materials such as wood, used papers, cardboard, and other recycled paper products. All these raw materials may contain some impurities which can damage the paper mill machineries and the quality of the paper.

To get rid of these impurities a cleaner is used. Depending on the type and the weight of the impurities like heavy or light, the cleaner is distinguished as High-Density Cleaner and Low-Density Cleaner.

Let’s learn about the High-Density Cleaner in this blog and how high-density cleaner machinery improves pulp quality.

The Significance of Pulp Quality Enhancement

Pulp quality is the backbone of paper production, influencing the final product’s texture, strength, and printability. High-density cleaner machinery plays a pivotal role in elevating overall quality by efficiently removing impurities, ensuring a smoother papermaking journey.

Pulp Quality Enhancement is very crucial not only to improve the paper quality but eventually to help the life of other machinery in the production line as well. Since the impurities and heavy material in the pulp can damage the machineries like, screening baskets, refining plates, and other machineries resulting in reducing their lives, Pulp Quality Enhancement is important.

High-Density Cleaner

High-density cleaners are specifically designed to remove high and medium-density contaminants or contaminants with high and medium-specific gravities from stock. Contaminants such as rocks, nuts, bolts, nails, paperclips, staples, glass, and other heavy debris are removed by the cleaner. High-density cleaners are not designed to remove wax or other low-density or low-specific gravity materials.

How a High-Density Cleaner Works?

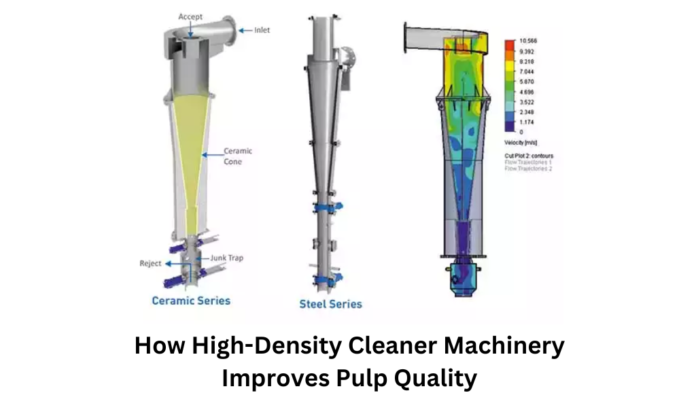

The stock suspension is pumped tangentially into the top of the cylindrical cleaner body at a relatively high velocity as the stock lows inward, centrifugal force and fluid shear create a vortex near the center of the cleaner. Dense materials move to the outside wall and drop down into a bottom rejects collection chamber. The fibers migrate to the center vortex and travel upwards to the accepted stock outlet.

The walls of the high-density cleaner help to reduce the speed of the impurities and drop them to the bottom to the reception chamber. Though there are normal HDC using different materials for manufacturing the walls, a special ceramic wall HDC known as High-Density Ceramic Cleaner (HDCC) is also available in the market. The use of ceramic in the High-Density Cleaner improves efficiency by reducing the speed of the heavy impurities immediately and providing a smooth operation.

How High-Density Cleaner Machinery Improves Pulp Quality

Enhanced Purity Levels

High-density cleaner machinery efficiently removes unwanted contaminants, ensuring a cleaner and more refined final product. It helps to increase the purity of the pulp. As there are no major contaminants and the pulp has gained more purity the end product quality eventually increases.

Improved Strength and Durability

The removal of impurities results in pulp with enhanced strength and durability, crucial factors that directly impact the quality and longevity of the end product.

Consistent Quality Standards

The precision of high-density cleaner machinery guarantees consistent quality standards, eliminating variations and ensuring uniformity in each batch of pulp.

Frequently Asked Questions

How does high-density cleaner machinery work?

High-density cleaner machinery utilizes advanced filtration and separation techniques to remove impurities from pulp, resulting in a cleaner and higher-quality product.

What are the key benefits of using high-density cleaner machinery?

The primary benefits include enhanced purity levels, improved strength and durability, and the maintenance of consistent quality standards throughout production.

Is the integration of high-density cleaner machinery cost-effective?

Yes, the long-term benefits, including increased production efficiency and reduced resource consumption, make the integration of high-density cleaner machinery a cost-effective investment.

Can high-density cleaner machinery be customized for different pulp types?

Absolutely, modern high-density cleaner machinery is designed with versatility in mind, allowing customization for various pulp types and production requirements.

Are there any environmental benefits associated with using high-density cleaner machinery?

Certainly, the efficient removal of impurities by these machines contributes to a more sustainable and environmentally friendly pulp production process.

How does high-density cleaner machinery impact the overall competitiveness of a paper mill?

The improved pulp quality and operational efficiency achieved with high-density cleaner machinery directly contribute to the competitiveness of a paper mill in the industry.

Conclusion

In conclusion, the integration of high-density cleaner machinery marks a significant leap forward in the quest for unparalleled pulp quality. This technology not only refines the production process but also aligns with sustainable practices, making it a cornerstone for the future of pulp and paper manufacturing.