- Recycled Paper Manufacturing Process

- Introduction

- What Is A Recycled Paper?

- Importance of Recycled Paper Manufacturing

- How Does Recycled Paper Manufacturing Process Work?

- Environmental Benefits of Recycled Paper

- FAQs

- What types of paper can be recycled?

- Is recycled paper of lower quality than virgin paper?

- How does recycled paper benefit the environment?

- Can recycled paper be recycled again?

- Are there any drawbacks to recycled paper manufacturing Process?

- What can individuals do to support recycled paper manufacturing?

- Conclusion

Recycled Paper Manufacturing Process

Introduction

In today’s environmentally conscious world, the demand for sustainable products is on the rise. One such industry that has seen significant growth is recycled paper manufacturing. This article explores the intricate recycled paper manufacturing process, highlighting its environmental benefits, technological advancements, and future prospects.

What Is A Recycled Paper?

Recycled paper is an eco-friendly alternative to traditional paper made from virgin wood pulp. It is produced by collecting discarded paper products, such as newspapers, magazines, and cardboard, and processing them into new paper products. This process not only conserves natural resources but also reduces waste and pollution.

Importance of Recycled Paper Manufacturing

Recycled paper manufacturing process plays a crucial role in conserving forests, reducing energy consumption, and minimizing landfill waste. By utilizing recycled fibers, the demand for virgin wood pulp is reduced, leading to the preservation of forests and biodiversity.

How Does Recycled Paper Manufacturing Process Work?

Collection and Sorting

The first step in the recycled paper manufacturing process is the collection and sorting of recyclable paper materials. Recycling centers and waste management facilities gather paper waste from various sources, including households, businesses, and industries.

Automated Sorting Technologies

Advancements in technology have revolutionized the sorting process, with automated systems using optical scanners and conveyor belts to separate different types of paper based on their grade, color, and texture. This ensures efficient and accurate sorting, optimizing the recycling process.

Pulping

Once sorted, the recycled paper is pulped to break down the fibers and remove contaminants. Pulping can be done through mechanical or chemical methods, depending on the quality of the recycled paper required.

Mechanical pulping involves shredding the paper into small pieces and mixing them with water to create a pulp slurry. This slurry is then refined through screens and filters to remove impurities, resulting in a coarse pulp suitable for products like cardboard and newsprint.

Chemical pulping utilizes chemicals, such as sodium hydroxide and sodium sulfide, to dissolve the lignin and separate the fibers. This process produces a higher quality pulp suitable for producing fine paper products, such as office paper and packaging materials.

Deinking

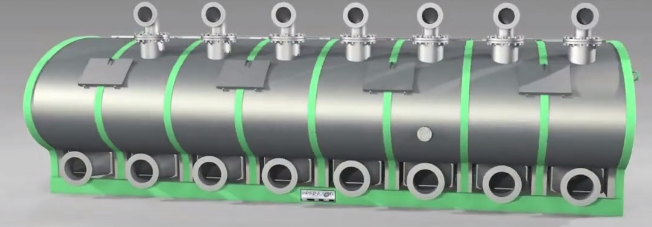

Deinking System

After pulping, the recycled pulp undergoes a deinking process to remove ink and other contaminants. Deinking can be achieved through various methods, including flotation, washing, and bleaching. The Deinking Cell is used to complete this process.

The Deinking Cell is a machine with several connected sections that help clean paper pulp. It has a special shape and a baffle (a barrier) to separate different parts. Air and the pulp, which is the mixture used to make paper, go into the machine through a special nozzle. The nozzle creates a suction force that helps mix the air and pulp, making tiny bubbles. These bubbles help remove unwanted bits from the pulp, making the paper brighter and cleaner. The machine controls how much air is added and the size of the bubbles.

Once the ink is removed from the pulp, it moves to the next section of the machine. The ink and bubbles that are removed float to the top and are collected separately. This process helps make the paper cleaner and brighter by removing unwanted particles.

Papermaking

The deinked pulp is then ready for the papermaking process, where it is formed into sheets and dried to produce recycled paper. Papermaking involves several steps, including forming, pressing, drying, and finishing.

Forming

In the forming stage, the pulp slurry is poured onto a wire mesh conveyor, allowing water to drain through while retaining the fibers to form a wet paper sheet.

Pressing and Drying

The wet paper sheet passes through press rollers to remove excess water, then moves through heated drying cylinders to evaporate the remaining moisture, resulting in a dry paper sheet ready for finishing.

Finishing and Packaging

Once dried, the recycled paper undergoes finishing processes, such as calendering and coating, to improve its smoothness, brightness, and printability. The finished paper is then cut, packaged, and distributed to consumers and businesses.

Environmental Benefits of Recycled Paper

Recycled paper manufacturing process offers numerous environmental benefits, including:

- Conservation of Resources: By reducing the demand for virgin wood pulp, recycled paper manufacturing helps conserve forests and wildlife habitats.

- Energy Savings: Recycling paper requires less energy than producing paper from virgin materials, leading to reduced greenhouse gas emissions and fossil fuel consumption.

- Waste Reduction: Recycling paper diverts waste from landfills, where it would otherwise contribute to pollution and environmental degradation.

- Water Conservation: The recycled paper manufacturing process consumes less water than traditional papermaking, helping to conserve this precious resource.

As awareness of environmental issues continues to grow, the demand for recycled paper products is expected to increase. Technological innovations in recycling and papermaking processes will further improve the efficiency and sustainability of recycled paper manufacturing, paving the way for a greener and more sustainable future.

FAQs

What types of paper can be recycled?

Recycled paper can include various types of paper products, such as newspapers, magazines, office paper, cardboard, and packaging materials.

Is recycled paper of lower quality than virgin paper?

No, recycled paper can achieve the same quality standards as virgin paper through advanced recycling and deinking processes.

How does recycled paper benefit the environment?

Recycled paper manufacturing helps conserve forests, reduce energy consumption, minimize waste, and preserve natural resources.

Can recycled paper be recycled again?

Yes, recycled paper can undergo multiple recycling cycles without significant loss of quality, making it a sustainable choice for paper products.

Are there any drawbacks to recycled paper manufacturing Process?

While recycled paper offers many environmental benefits, it may require additional processing and treatment compared to virgin paper, leading to higher production costs in some cases.

What can individuals do to support recycled paper manufacturing?

Individuals can contribute to recycled paper manufacturing by recycling paper products, purchasing recycled paper products, and advocating for sustainable practices in their communities.

Conclusion

The recycled paper manufacturing process offers a sustainable solution to the growing demand for paper products while mitigating environmental impact. By understanding the intricate steps involved in recycled paper manufacturing and supporting eco-friendly practices, we can all contribute to a greener and more sustainable future.