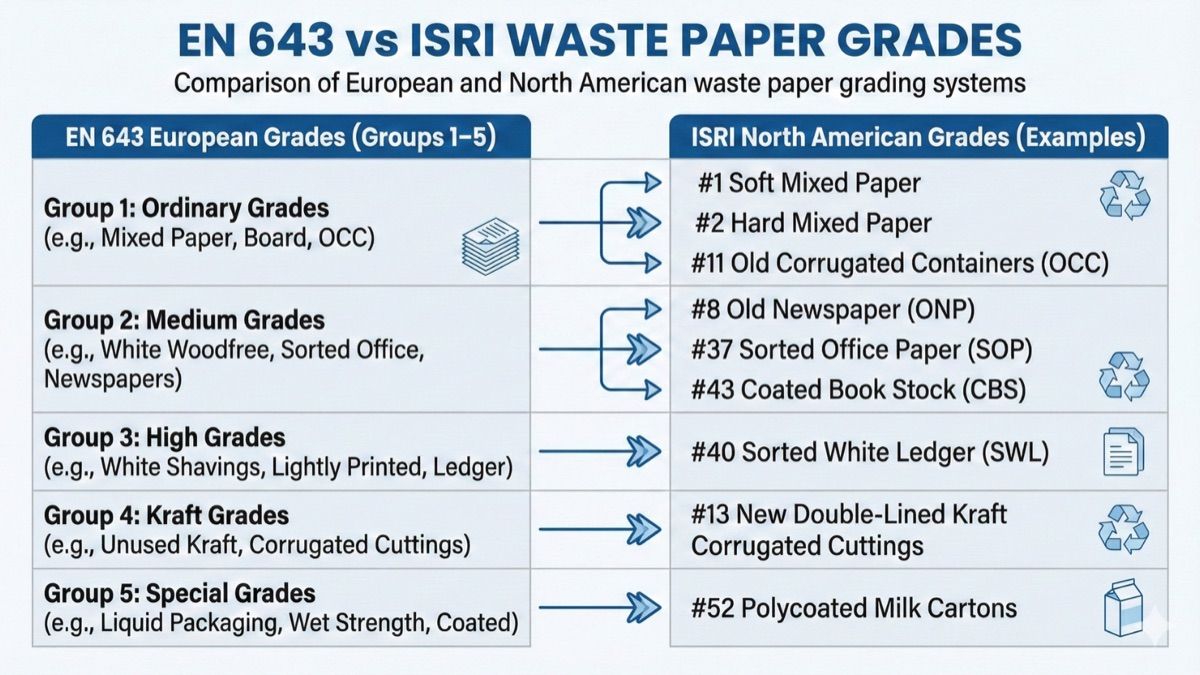

Waste paper grades are standardized classifications for recycled paper based on fiber type, contamination levels, and intended application. The two primary international systems—ISRI (American) and EN 643 (European)—define specifications that determine pricing, quality expectations, and suitable end products for each grade. The ISRI system is the most widely used classification for waste paper trading globally.

With over 50% of global paper production now utilizing recycled fiber, understanding waste paper grades has become essential for mill profitability and product quality. Recycled fiber accounts for 35-60% of furnish in many paper grades, and global recovered paper utilization exceeds 250 million tonnes annually.

Selecting the right waste paper grades directly impacts production costs, machine runnability, and final product specifications. This comprehensive guide covers the ISRI (American) and EN 643 (European) classification systems, detailed specifications for each grade category, contamination management, and practical guidance for blending different waste paper grades to achieve target strength and quality.

Understanding Waste Paper Classification Systems

Two primary standards govern international waste paper trade: the ISRI (American) specifications and the European EN 643 standard. The ISRI system is the most widely used classification for waste paper trading globally, and this guide follows ISRI as the primary reference.

ISRI Paper Stock Specifications (Primary Standard)

The Recycled Materials Association (ReMA, formerly ISRI) publishes the Scrap Specifications Circular, updated in 2024. This American standard uses Paper Stock (PS) grade numbers and specifies limits for prohibitives (materials that render a load unacceptable) and outthrows (materials requiring removal before processing).

ISRI grades are organized into functional categories:

Key ISRI terminology:

- Outthrows: Materials in a bale that are not the specified grade but are recyclable paper. Typical limit: 2-5%.

- Prohibitives: Non-paper materials or papers that are harmful to the recycling process. Typical limit: 0.5-1%.

ISRI to EN 643 Cross-Reference

EN 643 European Standard (Secondary Reference)

The European List of Standard Grades (EN 643) was developed by CEPI (Confederation of European Paper Industries). The current revision dates to 2014 and organizes grades into five main groups.

EN 643 specifies maximum tolerance levels for non-paper components (1.5% for most grades) and grade-specific limits for unwanted materials. Mills sourcing from European markets should be familiar with this system alongside ISRI.

Corrugated and Mixed Paper Grades (ISRI PS 1-14)

Corrugated and mixed paper grades represent the highest-volume waste paper categories, dominated by old corrugated containers (OCC). These grades form the backbone of recycled packaging production globally.

PS 1 - Mixed Paper

This lowest-tier ISRI grade consists of various paper and board types collected without sorting. Mills accepting this grade must invest heavily in cleaning systems to remove contaminants.

- Outthrows: Included in definition (mixed by nature)

- Prohibitives: Maximum 2%

- Typical yield: 70-80%

- EN 643 equivalent: 1.01 (Mixed paper and board, unsorted)

- Applications: Chipboard, construction paper, low-grade recycled boards

PS 20 - Sorted Mixed Paper

A step above unsorted mixed paper, this grade undergoes basic sorting to remove obvious contaminants and limit non-paper content.

- Outthrows: Maximum 10%

- Prohibitives: Maximum 1%

- EN 643 equivalent: 1.02 (Mixed paper and board, sorted)

- Applications: Recycled liner, folding boxboard middle layer

PS 11 - Old Corrugated Containers (OCC)

OCC is the single largest waste paper grade by global trading volume. This grade consists of used corrugated boxes and sheets, serving as the primary raw material for testliner and fluting production.

- Outthrows: Maximum 5%

- Prohibitives: Included in outthrows percentage

- EN 643 equivalent: 1.05

- Applications: Testliner, fluting medium, kraft liner supplement

PS 12 - Double-Sorted Old Corrugated Containers (DSOCC)

DSOCC undergoes a second sorting pass, resulting in significantly cleaner material. This grade commands a premium over standard OCC and is widely used to improve furnish quality.

- Outthrows: Maximum 2%

- Prohibitives: Maximum 0.5-1%

- EN 643 equivalent: 1.06 (Sorted OCC)

- Applications: Premium testliner, high-quality fluting, strength improvement in blends

OCC Grade Comparison

PS 13 - New Double-Lined Kraft Corrugated Cuttings

Factory cuttings and trimmings from corrugated box manufacturing. Clean, uncontaminated material with excellent strength properties.

- Outthrows: Maximum 1%

- Prohibitives: Maximum 0.5%

- EN 643 equivalent: 4.01

- Applications: Premium kraftliner, high-strength fluting

PS 14 - New Corrugated Kraft Cuttings

New single-wall corrugated cuttings from converting plants.

- Outthrows: Maximum 1%

- Prohibitives: Maximum 0.5%

- EN 643 equivalent: 4.06

- Applications: High-strength packaging, kraftliner

News and Magazine Grades (ISRI PS 2-10)

News and magazine grades are primarily intended for deinking operations producing recycled newsprint, tissue, and printing papers. Fiber quality and deinkability are critical selection factors.

PS 7 - #1 News (ONP Regular)

Old newspapers represent the primary feedstock for deinked pulp production. Quality requirements include freshness (not sunburned) and dryness.

- Outthrows: Maximum 2%

- Prohibitives: Maximum 1%

- Deinkability: Excellent

- Achievable brightness: 58-65%

- EN 643 equivalent: 2.01 (Newspapers)

- Applications: Newsprint, tissue, packaging (after deinking)

PS 8 - Special News Deink Quality

Higher-quality newspaper grade specifically sorted for deinking operations, with tighter contamination limits than PS 7.

- Outthrows: Maximum 2%

- Prohibitives: Maximum 0.5%

- Achievable brightness: 60-68%

- EN 643 equivalent: 2.01

- Applications: Premium deinked pulp, recycled tissue

PS 10 - Magazines (OMG)

PS 2 - Mixed News and Magazines

This mixed deinking grade combines ONP with old magazines, requiring adjusted deinking chemistry to handle coated papers.

- Outthrows: Maximum 5%

- Prohibitives: Maximum 1%

- Achievable brightness: 55-62%

- EN 643 equivalent: 2.02

- Applications: Newsprint, SC paper, recycled tissue

High Grades (ISRI PS 37-48)

High grades command premium prices due to their superior fiber quality, brightness potential, and low contamination levels. These grades are essential for producing recycled office papers and premium tissue.

ISRI High Grade Specifications

PS 42 - Hard White Shavings (HWS)

The highest-value recovered paper grade consists of unprinted, groundwood-free white paper shavings and cuttings.

- Source: Printing plants, converters

- Outthrows: Maximum 0.5%

- Prohibitives: Maximum 0.5%

- EN 643 equivalent: 3.05 (White woodfree shavings)

- Applications: Premium writing papers, facial tissue

PS 37 - Sorted White Ledger (SWL)

White uncoated papers, free of groundwood, sorted for high brightness potential.

- Outthrows: Maximum 2%

- Prohibitives: Maximum 0.5%

- Key requirement: No colors, no carbons

- Applications: High-quality recycled writing papers, premium tissue

PS 40 - Sorted Office Paper (SOP)

Mixed office waste paper including white and lightly colored papers, computer printout, and office forms.

- Outthrows: Maximum 5%

- Prohibitives: Maximum 1%

- EN 643 equivalent: 3.01

- Applications: Recycled office paper, tissue, printing grades

Kraft Grades (ISRI PS 31-54)

Kraft grades contain long softwood fibers providing superior strength properties. These grades are critical for mills seeking to improve strength in their furnish through waste paper blending rather than virgin fiber addition.

PS 54 - Sack Kraft (Grocery Bag Kraft)

Sack Kraft consists of used brown kraft grocery bags, shopping bags, and similar unbleached kraft paper. This grade is widely used in developing markets to improve the strength of OCC-based furnish.

- Outthrows: Maximum 2%

- Prohibitives: Maximum 1%

- Fiber type: Long softwood kraft (2.5-4.0 mm)

- EN 643 equivalent: 4.03 (Used kraft sacks)

- Applications: Blending with local OCC to improve burst, tensile, and ring crush

Key Characteristics of Kraft Grades

- Fiber type: Long softwood kraft (2.5-4.0 mm)

- Strength contribution: Excellent tear and tensile

- Availability: Limited compared to OCC

- Pricing: Premium (approaching virgin kraft values)

- Primary use in blending: Added to OCC furnish to boost strength properties

- Contamination concerns: Used sacks may contain cement, food residues

Special Grades (ISRI / EN 643 Group 5)

Special grades require specialized processing equipment and present unique challenges for recyclers.

Grade 5.01 - Liquid Packaging Board

Beverage cartons (Tetra Pak, juice cartons, milk cartons) contain valuable fiber but require separation from plastic and aluminum layers using specialized pulper equipment.

Grade 5.03 - Wet Strength Papers

Papers containing wet strength resins (polyamide epichlorohydrin, glyoxalated PAM) resist water dispersion and require extended pulping times with chemical treatment.

- Processing time: 2-4x standard pulping

- Chemical requirements: Hypochlorite or enzyme treatment

- Applications: Often limited to energy recovery

Grade 5.07 - Labels and Adhesive Papers

Self-adhesive papers represent a major source of stickies contamination. Specialized processing with aggressive screening and flotation is required.

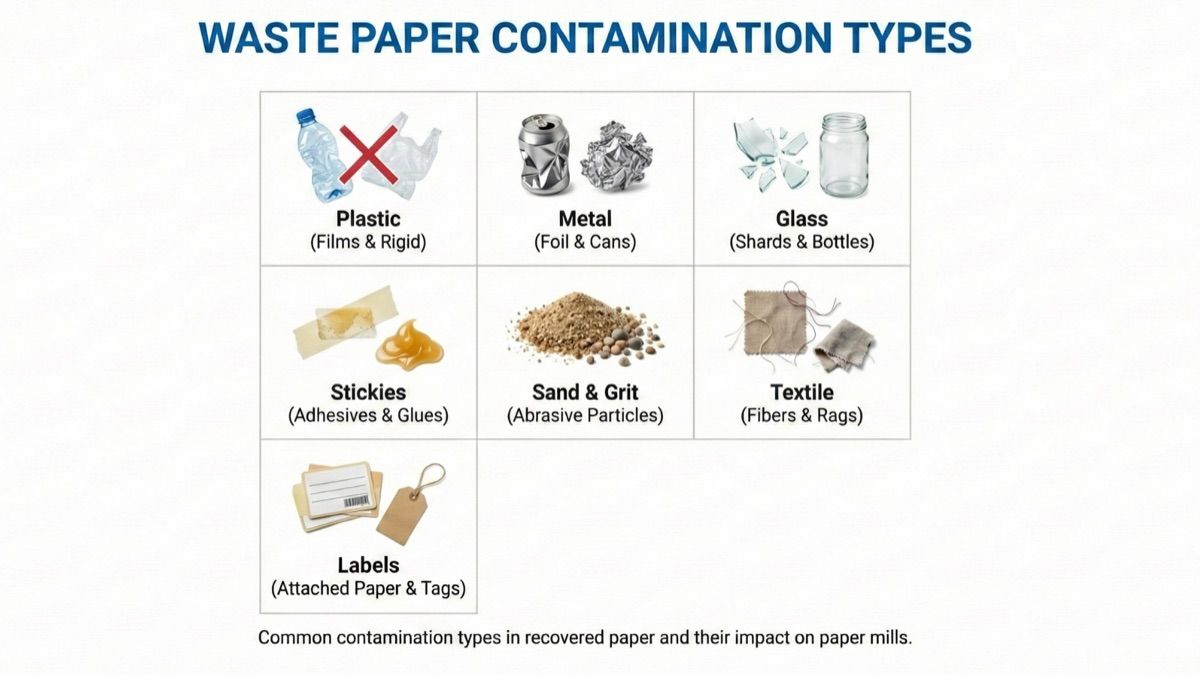

Contamination Types and Tolerance Limits

Contamination management is critical for machine runnability and product quality. Understanding contamination categories helps mills establish effective quality control programs.

Prohibited Materials (Zero Tolerance)

These materials must never enter the waste paper stream:

- Medical and hygiene waste

- Hazardous materials (batteries, chemicals, paint)

- Food waste causing wet contamination

- Bitumen/asphalt-coated papers

- Carbon paper (most grades)

- Sanitary products

Non-Paper Components

Stickies: The Most Problematic Contaminants

Stickies cause machine deposits, felt plugging, and sheet defects. Understanding their sources enables better incoming material control.

Chemical Composition of Stickies:

- Polyvinyl acetate (PVA)

- Styrene butadiene rubber (SBR)

- Ethylene vinyl acetate (EVA)

- Paraffin waxes

Moisture Specifications

Blending Different Waste Paper Grades for Strength

In practice, mills achieve target strength properties by blending different grades of waste paper rather than adding virgin fiber. The most common approach is blending locally sourced OCC with higher-quality imported grades such as American OCC, DSOCC, or Sack Kraft. This strategy delivers cost-effective strength improvement while maintaining a fully recycled furnish.

Why Blend Different Waste Paper Grades?

- Improve strength properties - Higher-grade waste papers (DSOCC, Sack Kraft) contain longer, stronger fibers than local OCC

- Manage quality variation - Local OCC quality varies by region; imported grades provide consistency

- Optimize costs - Blending premium grades at 20-40% is more economical than using them at 100%

- Control contamination - Double-sorted and kraft grades dilute contaminant levels in local OCC

Common Blending Strategies for Packaging Mills

Fiber Property Comparison Across Waste Paper Grades

Note: American OCC is generally stronger than local OCC in many developing markets because American corrugated boxes use a higher proportion of virgin kraft fiber in their original manufacture. This results in longer fibers even after recycling.

Blending for Deinking Grades

Hornification and Recycling Limits

Hornification refers to the irreversible stiffening and collapse of fiber structure during drying cycles. This phenomenon limits effective paper recycling to 5-7 cycles.

Mitigation strategies:

- Blending with higher-quality waste paper grades (DSOCC, Sack Kraft, New DLK)

- Refining (limited benefit due to already shortened fibers)

- Enzyme treatments to restore fiber swelling

- Chemical swelling agents (starch, CMC)

- Strength additives (cationic starch, dry strength resins)

Grade Selection by End Product

Selecting appropriate waste paper grades requires matching fiber properties to product specifications.

Packaging Grade Selection

Printing/Writing Paper Selection

Tissue Grade Selection

Advantages and Disadvantages of Waste Paper

Advantages

Disadvantages

Economic Considerations: Grade Blending

Quality Testing for Incoming Waste Paper

Effective quality control begins with systematic incoming material testing.

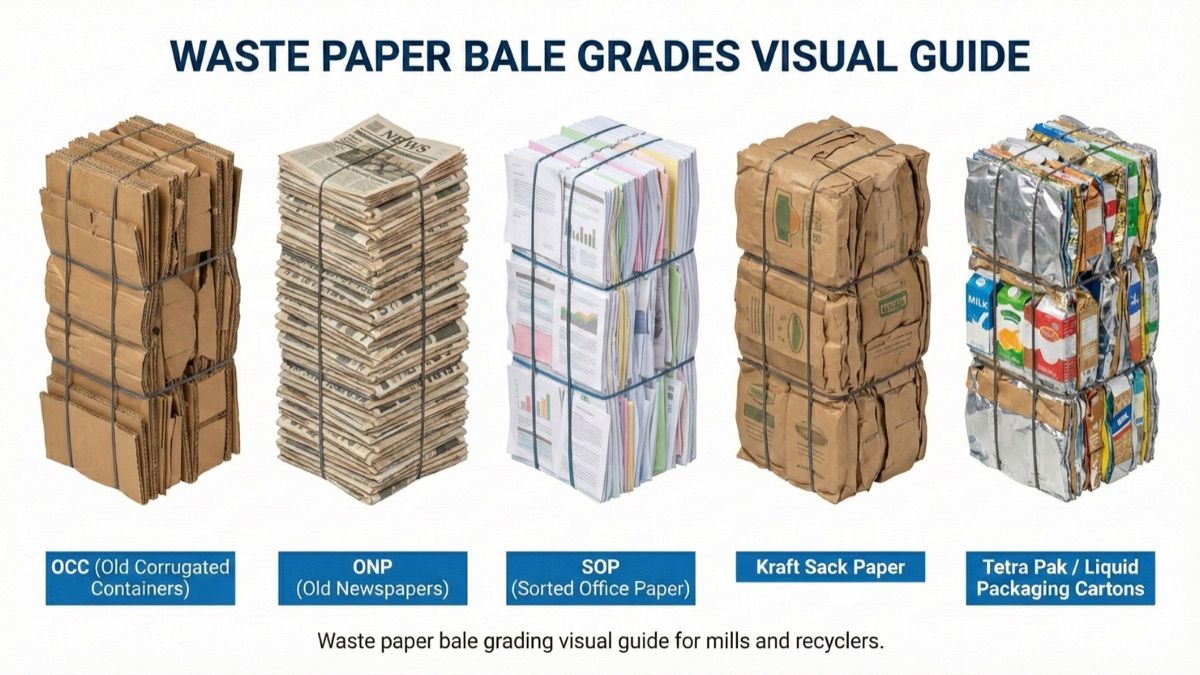

Visual Inspection Protocol

- Bale exterior examination for contamination

- Core sampling (5-10 samples per load)

- Moisture estimation

- Grade verification against specifications

Laboratory Testing Methods

Key Takeaways

- ISRI (American) and EN 643 (European) provide standardized classification systems enabling international waste paper trade

- ISRI grades cover all recovered paper types: Mixed Papers, Corrugated, News/Magazine, High Grades, Kraft Grades, and Special Grades

- OCC (ISRI PS 11) represents the largest single grade by global trading volume

- Mills improve strength by blending different waste paper grades—local OCC with American OCC, DSOCC (PS 12), or Sack Kraft (PS 54)—rather than adding virgin fiber

- Stickies from adhesives, wax, and latex represent the most problematic contaminants for machine runnability

- Paper fibers can be effectively recycled 5-7 times before hornification limits further use

- American OCC provides stronger fiber than local OCC in many markets due to higher virgin kraft content in original manufacture

- Cost savings of 20-50% versus virgin pulp, with 40-70% energy reduction

- Proper grade selection and blending strategy based on end-product requirements optimizes both quality and economics

Conclusion

Waste paper grades provide essential raw material for sustainable paper production, with recycled fiber now comprising the majority of furnish for many paper grades globally. Understanding the ISRI and EN 643 classification systems enables mills to source appropriate grades for their specific product requirements.

Effective contamination management—particularly stickies control—remains critical for machine runnability and product quality. Strategic blending of different waste paper grades—such as local OCC with American OCC, DSOCC, or Sack Kraft—enables mills to meet target strength specifications without relying on virgin fiber, while optimizing the economic and environmental benefits of paper recycling.

For mills looking to optimize their recycled fiber processing, investing in advanced stock preparation equipment and cleaning systems delivers measurable improvements in both efficiency and final product quality. Explore equipment options suited to your specific waste paper grades and production requirements.