From the outside, a disc filter and a disc thickener look almost identical — rotating discs submerged in a vat of stock. Both serve the same purpose: separating water from fiber to increase pulp consistency. Yet the dewatering principle inside each machine differs fundamentally, and that difference has a direct impact on mill profitability.

When comparing a disc filter vs disc thickener for pulp thickening, the choice affects outlet consistency, fiber recovery, backwater quality, and total cost of ownership. This article presents measurable performance data across these parameters so mill engineers can make a data-driven equipment selection.

What Is the Difference Between a Disc Filter and a Disc Thickener?

Both machines use rotating discs fitted with sector plates, submerged in a stock vat. The similarity ends there.

Poly disc filter (PDF): Vacuum is created by a barometric leg — a water column approximately 10 m in height. This passive system generates vacuum without any mechanical pump or electrical power for dewatering. As discs rotate through the stock, vacuum draws water through the filter media and forms a dense fiber mat on each sector plate surface. A filtrate valve at the barometric leg separates the collected water into clear, super-clear, and cloudy grades.

Gravity disc thickener: Water drains through the sector plates by hydrostatic head difference alone — the liquid level inside the sector is higher than outside. There is no vacuum, no barometric leg, and no filtrate separation. Filtrate exits through hollow shaft ends by gravity only.

The barometric leg provides significantly greater driving force than gravity alone. This single engineering difference explains the performance gap detailed in the sections below.

Section Summary: The fundamental difference is the dewatering mechanism — vacuum via barometric leg versus gravity-only hydrostatic drainage. This difference in driving force directly determines outlet consistency, fiber recovery, and filtrate quality.

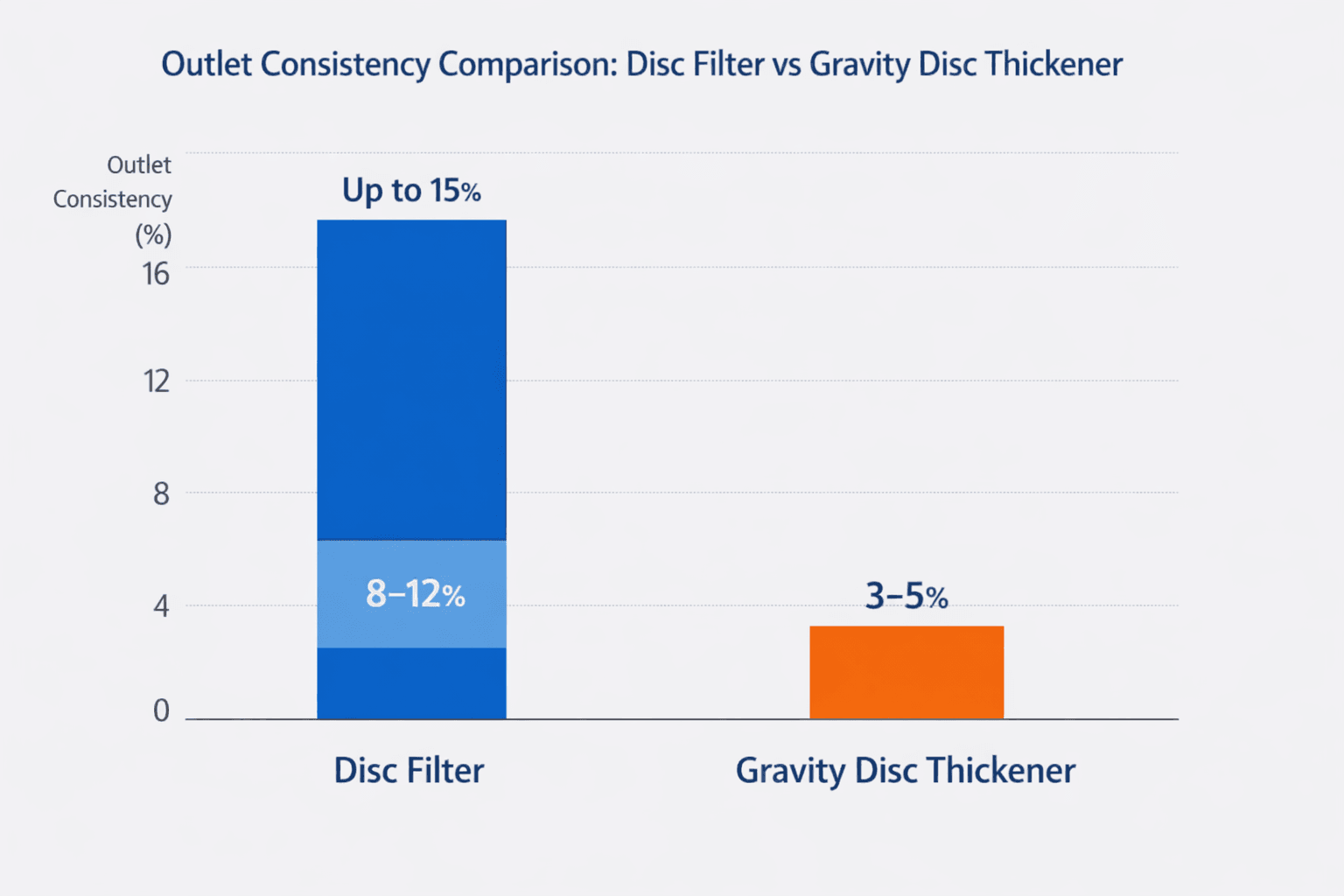

What Outlet Consistency Does Each Machine Achieve?

The outlet consistency gap between these two technologies is substantial. A disc filter produces 8–12% outlet consistency in a single pass, while a gravity disc thickener reaches only 3–5%. That is more than double the thickening from disc filtration.

For mills targeting 10%+ consistency before storage towers or high-density processing, a disc filter achieves this in one pass. A gravity disc thickener at 3–5% outlet would require additional downstream equipment to reach the same target.

Section Summary: Disc filters achieve 8–12% outlet consistency with 95–99% fiber recovery — more than double the 3–5% from gravity disc thickeners. The vacuum-driven fiber mat also yields multi-grade filtrate as clean as 100–200 PPM versus 800+ PPM from gravity drainage.

Backwater Quality and Fine Retention

Vacuum filtration creates a fiber mat on the disc surface during each rotation cycle. This mat acts as a secondary filter barrier, capturing fines and fillers that would otherwise pass through the filter media. The result is clear filtrate at 100–200 PPM and cloudy filtrate at 300–500 PPM.

A gravity disc thickener lacks this vacuum-driven mat formation. Fines pass through the sector plates freely, producing single-grade filtrate at 800+ PPM. The downstream consequences of this difference are measurable:

- Lower ETP load — Cleaner disc filter backwater reduces the suspended solids entering effluent treatment

- Process water reuse — Multi-grade filtrate allows targeted reuse: super-clear for showers, clear for dilution, cloudy returned to process

- Reduced chemical demand — Retained fines lower the need for replacement additives and retention aids

- Improved sheet formation — Recovered fines returned to the stock system contribute to better sheet uniformity and reduced variability in basis weight

The difference in backwater quality also affects downstream chemical costs. When fines are lost to the ETP, the stock system requires additional retention aids, fillers, and strength additives to compensate. A disc filter returning 95–99% of fiber to the process reduces this chemical burden measurably.

Power Consumption and Operating Cost

A common misconception holds that disc filters consume more power due to vacuum generation. This is incorrect. The barometric leg creates vacuum through a static water column (~10 m height) — a gravity-driven, zero-energy process with no mechanical pump involved.

Both machines require only a rotation drive motor, typically in the 11–22 kW range for comparable capacities. The power consumption per tonne of pulp processed is similar for both machines at the equipment level.

The real operating cost difference lies at the system level. A disc filter delivering 8–12% consistency reduces or eliminates the need for additional downstream thickening stages. A gravity disc thickener producing 3–5% may require supplementary equipment — such as a screw press or inclined screw thickener — to reach the target consistency for storage or further processing. That additional equipment adds both capital cost and energy consumption to the line.

When evaluated on a per-tonne basis across the full thickening line, the disc filter typically delivers lower total energy cost despite identical motor power at the machine level.

Process Control and Flexibility

The disc filter offers three independent control variables: disc rotation speed (VFD), vacuum level (barometric leg valve adjustment), and filtrate separation (multi-grade valve). Operators can adjust outlet consistency and filtrate quality independently, adapting to changes in inlet conditions, fiber type, or process demand.

The gravity disc thickener provides one control variable — disc rotation speed via VFD. Outlet consistency and filtrate quality vary together and cannot be independently optimized.

For mills running multiple grades or experiencing frequent consistency swings in the feed, the disc filter's additional control points provide measurably better process stability. The ability to separate filtrate into three grades also allows operators to direct water of different quality to appropriate reuse points — super-clear filtrate for high-pressure showers, clear filtrate for stock dilution, and cloudy filtrate back to the process chest.

Which Has Better ROI: Disc Filter or Disc Thickener?

On purchase price alone, the gravity disc thickener is the more economical option. It installs at floor level with minimal civil works and lower equipment cost. The disc filter requires an elevated platform or multi-level structure to accommodate the barometric leg, adding civil engineering cost to the project.

However, total cost of ownership tells a different story:

The fiber recovered at 95–99% efficiency, the reduction in ETP operating costs, the lower chemical consumption, and the elimination of downstream thickening stages collectively offset the initial civil investment. For mills processing 100+ t/d, these savings compound rapidly.

Consider a mill processing 200 t/d of pulp. Even a 2–3% improvement in fiber recovery translates to 4–6 tonnes of fiber saved per day. At typical fiber costs, this saving alone can justify the additional civil investment within the first year of operation.

Section Summary: While gravity disc thickeners cost less upfront, disc filters deliver superior total cost of ownership for mills above 100 t/d. Fiber recovery savings of 4–6 tonnes/day at a 200 t/d mill can justify the civil works investment within the first year.

Installation Considerations

The disc filter requires elevated installation to accommodate the barometric leg — a water column of approximately 10 m. This means either a raised structural platform or a multi-level building design, adding civil engineering scope and cost to the project.

The gravity disc thickener installs at floor level with standard foundations, making it simpler to integrate into existing layouts with minimal structural modification. For retrofit projects where building height is constrained, this can be a deciding factor.

The elevated installation is typically justified when:

- Mill capacity exceeds 100 t/d

- Target outlet consistency is above 8%

- Fiber recovery targets are 95%+ for economic or environmental reasons

- ETP operating costs are a significant line item

- Process water quality requirements demand multi-grade filtrate

- The mill has new construction or expansion planned (civil costs are lower when integrated into new design)

For smaller mills with low throughput and no stringent fiber recovery requirements, a gravity disc thickener may provide adequate performance at lower capital cost. The choice depends on the specific mill's production targets, fiber cost, and available infrastructure.

When Should You Choose a Disc Filter vs a Disc Thickener?

Not every application demands the higher performance of a disc filter. Here is a practical selection guide:

Choose a disc filter when:

- Outlet consistency above 8% is required in a single pass

- Fiber recovery rates of 95%+ are critical to your operation

- Clean backwater (under 300 PPM) is needed for process water reuse

- The mill operates at 100+ t/d capacity

- Multi-grade filtrate separation adds value to your water management

Choose a gravity disc thickener when:

- Moderate thickening to 3–5% is sufficient for the next process stage

- Capital budget is limited and floor-level installation is preferred

- Building height constraints prevent barometric leg installation

- The application involves pre-thickening before a second-stage thickener

- Production volume is under 100 t/d with moderate fiber recovery needs

Both technologies serve valid roles in stock preparation. The key is matching the equipment capability to the actual process requirement rather than defaulting to the lowest upfront cost.

Can a Disc Filter Work as a Save-All System?

Beyond primary thickening, disc filters serve a second function as save-all systems. Save-all equipment recovers fiber from white water — wire pit and couch pit drainage — before it reaches the effluent treatment plant. The process routes dilute white water (0.1–0.5% consistency) through the disc filter, where vacuum filtration captures fine fibers into a mat that returns to the stock system.

Gravity disc thickeners are not suited for save-all service. At the low consistencies typical of white water, gravity drainage alone cannot form a fiber mat or retain fines effectively. This dual capability — thickening and fiber recovery — adds a secondary return on the disc filter investment that gravity thickeners cannot match.

For mills that currently send white water directly to ETP, adding a disc filter as a save-all can reduce effluent suspended solids by 60–80%, lowering both treatment costs and environmental compliance risk.

Key Takeaways

- Disc filters use barometric leg vacuum (zero power) to achieve 8–12% outlet consistency — more than double the 3–5% from gravity disc thickeners

- The barometric leg is a passive vacuum system requiring no mechanical pump — only elevated installation (~10 m height)

- Vacuum-formed fiber mats capture fines that gravity cannot, producing filtrate as clean as 100–200 PPM vs 800+ PPM

- Multi-grade filtrate separation (clear, super-clear, cloudy) enables targeted process water reuse throughout the mill

- Higher upfront cost for civil works is offset by fiber recovery savings, reduced ETP load, and reduced chemical consumption

- Disc filters also serve as save-all systems for white water fiber recovery — a function gravity disc thickeners cannot perform

- For mills prioritizing fiber recovery, backwater quality, and total cost of ownership, disc filters deliver measurable ROI advantages over gravity disc thickeners

Conclusion

The disc filter vs disc thickener decision comes down to performance requirements and total cost of ownership. When fiber recovery rates above 95%, outlet consistency above 8%, and clean backwater matter to your operation, the disc filter's barometric leg vacuum delivers measurably superior results — despite higher initial investment in civil structure.

For mills where moderate thickening to 3–5% meets the process need, a gravity disc thickener remains a practical and cost-effective solution.

When evaluating pulp thickening equipment, look for designs featuring barometric leg vacuum, dedicated air removal, stainless steel construction, and multi-grade filtrate separation. These features determine long-term performance and return on investment.

Summary: Disc filters use barometric leg vacuum (zero power) to achieve 8–12% outlet consistency with 95–99% fiber recovery and filtrate as clean as 100–200 PPM. Gravity disc thickeners use hydrostatic drainage for 3–5% consistency at lower capital cost. For mills above 100 t/d targeting high fiber recovery and clean backwater, disc filters deliver superior total ROI despite higher civil works investment.