When you are looking for a refiner plate for your paper mill, you have to get one right as per your need. There are several best refiner plate manufacturers in India who provide the right refiner plate for your paper mill.

While purchasing the refiner plate for your paper mill, there are some factors you need to take into consideration to make sure that you are making the right decision. Let’s talk about those factors in this article to help you choose the right refiner plate for your paper mill.

What type of Refiner Plates do you need?

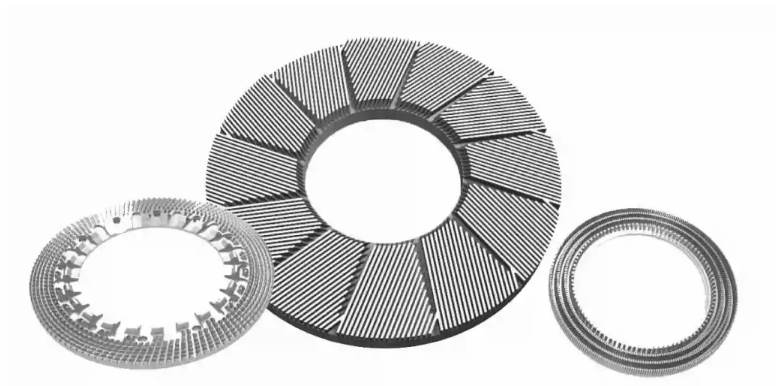

The primary function of a refiner plate is to refine or reduce the size of fibers in the pulp, ultimately affecting the quality of the paper produced. So first of all, you need to choose the type of refiner you need. You can choose from the single disk refiner, twin disk refiner, and double disk refiner.

Selecting The Right Refiner Plate

While choosing the refiner plate for your paper mill there are the following factors that you need to take into consideration:

- Net Refining Power

- Cutting Edge length

- Specific Edge Load

- Raw Material

- Fiber Length

- Required 0SR

- Type of Operation (Batch/Continuous)

- Arrangement of Refiner Street

- Throughput (Capacity)

- Material Used for Plate

- Budget

- Refiner Model

Net Refining Power

Before choosing the refiner plate you should check the refining power of the plate according to your production and use. This may affect the production and also impact the cost if not calculated correctly and not taken into consideration.

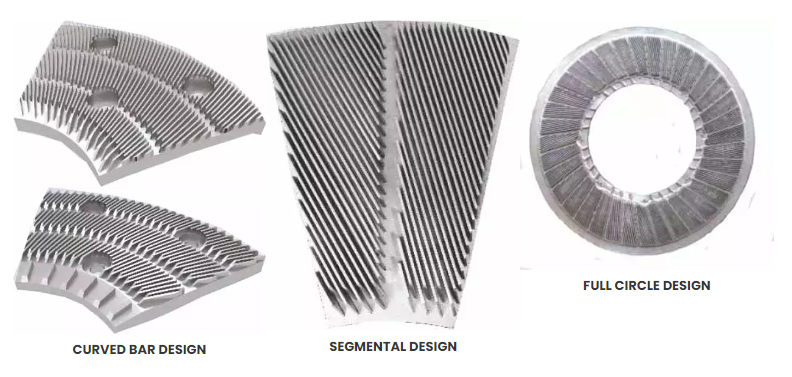

Cutting Edge Length And Specific Edge Load

According to the use of the raw material, the cutting-edge length and the specific edge load are noticed. This requires to take into consideration to design the bar pattern of the refiner plate. When your raw material is different, then these factors differ. Depending on these factors the bar pattern of the refiner plate needs to be designed.

Raw Material and Fiber Length

The raw material being used for pulp production has a crucial impact on the refiner plate. The size of the fiber and the length matters when it comes to raw material. This may impact the life of the refiner plate.

The fiber length is one of the important factors to care about while choosing the refiner plate as it may impact the life of the plate. Using the right refiner plate according to the fiber length used for pulp will result in a long-lasting refiner plate.

Required Schopper-Riegler Degree (0SR)

The freeness of the fiber of the pulp is crucial in production. To measure this freeness, a certain SR Degree is targeted. This SR degree is also a crucial factor to consider while choosing the refiner plate for your paper mill.

Type of Operation Batch

While processing the pulp production, the refining process is operated to refine the fibers and the pulp. The type of operation whether it is in batch or it is in continuous may also affect the life of the refiner plate. So, while choosing the right refiner plate one should take care of this factor.

Arrangement of Refiner Street

The arrangement of the refiner street is important to take into consideration while selecting the refiner plate. Depending on the arrangement whether it is in series or parallel or blend, the use of the refiner plate can be defined. It affects the life of the refiner plate depending on the arrangement.

Advertisement – Parason Refiner Fillings

Throughput (Capacity)

When selecting the refiner plate, the capacity of the production is a must factor to consider. What is the targeted production you are looking for can tell you which refiner plate should you choose.

Material Used For Plate

To have a long-lasting life of the refiner plate the alloy and the materials used in the production of the plate are very crucial. The perfect refiner plate according to your use may vary and it is dependent on the alloys which are used in the manufacturing of the plate.

Budget

The most important factor in choosing the right refiner plate for your paper mill is the budget. You do not want to imbalance things. The design, the material, and the type of plate you are choosing should fit into your budget. This might be considered as not a technical factor but it would be crucial when it comes to ROI.

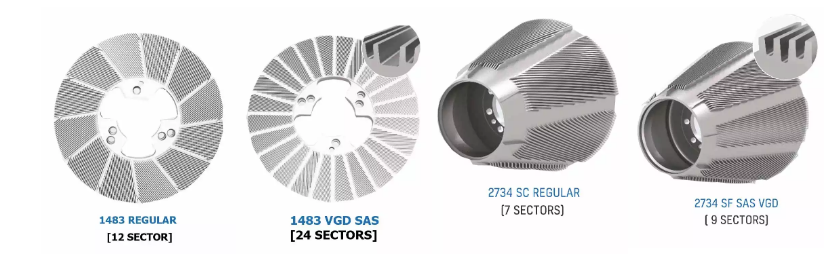

Refiner Model

By considering all the factors mentioned above one should select the right refiner plate for the paper mill. Although choosing the right refiner model is important. The difference in the model chosen may differ in the productivity and the capacity of the product. So, know your need and the targeted production to choose the right refiner model for your refiner plate.

So before going to decide whether which refiner plate to choose, one should take the above-mentioned factors into consideration for choosing the right refiner plate for your paper mill. There are several best refiner plate manufacturers in India where you can find the best quality paper mill machineries and services. Know your needs, and choose wisely.

To keep yourself updated with the latest trends in Paper Industry, keep visiting our blogs and write us in the comments section below. Thank you for reading.