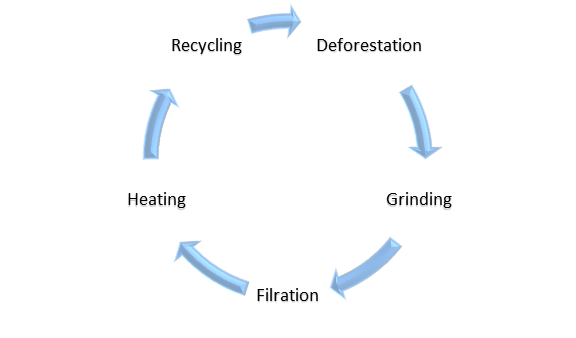

What do we mean by the life cycle of paper?

Like humans and plants, papers have their life cycles too.

It is the process that begins with the cutting down of trees and ends when the last cellulose fibers are no longer capable of forming sheets.

The life cycle of paper takes years to complete as each paper goes through several times of recycling before it becomes obsolete.

In this blog, we are going to discuss with you the complete life cycle of paper step by step. So let’s dive in and find out how the paper cycle works in nature.

Step 1: Deforestation –

This is the first step where the trees (special plantations that are done to obtain virgin fibers for making papers) are cut down.

The wood obtained from these trees is used to make the pulp.

The first papers are the higher grade papers as they are strong because they are produced from virgin pulp.

Step 2: Grinding –

This is the second step where the wood is chopped into small pieces and transformed into wood pulp with the help of machines or chemicals.

The process of making pulp with machines is termed mechanical pulping whereas the process that uses chemicals to form the pulp is called chemical pulping.

Step 3: Filtration –

Once the pulp is formed, the water in it is separated by filtering it through a wired mesh.

The process is sometimes referred to as screening and is carried out with screening machines.

Step 4: Heating –

The pulp is then run through heated rollers that squeezes out excess water and compress the pulp to form paper.

The paper sheets are then cut and transported for selling.

The final stage where the life cycle of the paper is continued is Recycling.

Step 5: Recycling –

The used paper is collected and sorted into different types according to its grades.

The paper is cleaned and the process is repeated from step 2.

This was the life cycle of paper from virgin pulp to recycling.

Similarly, recycled paper has a life cycle little different than virgin papers.

Also Read: What are the Essential Raw Materials Used in Paper Making?

Life Cycle of Recycled Paper

Recycled paper’s life cycle executes up to 6-7 times till the cellulose fibers become incapable of forming sheets.

The process of paper recycling is very impactful on the environment as it uses less energy, less power, less water, fewer gas emissions, reduces the amount of waste, and requires no wood for producing recycled papers.

The steps involved in the life cycle of recycled paper are as follows –

Step 1: Collection of waste paper – The waste paper (paper that has been used and thrown away) is collected from the waste sorting facilities and is classified into different grades and types depending on its quality, color, softness, hardness, etc.

This paper is sent to the recycling facility for producing new paper.

Step 2: Manufacture of recycled pulp –

The sorted waste paper is converted into pulp to regenerate higher grade paper.

This process is carried out using advanced technologies that help to produce paper with good quality, better brightness, and lower impurities.

The recycling of pulp includes main processes like deinking (for removing ink stains and dirt), cleaning (for removing impurities), and thickening (for improving pulp strength and forming sheets).

The process includes the use of different machines and equipment.

Step 3: Recycled Paper manufacture –

The recycled paper is manufactured from recycled pulp. The recycled pulp is prepared in a pulper machine which later undergoes processes like cleaning, dispersion, thickening, screening, deinking, and reject handling.

The pulp is poured from the headbox onto the wire mesh to mix it together.

It is later sent to the press section where it is pressed together to form sheets.

These sheets are passed through the drying section to form a strong paper sheet.

The sheets are coated with necessary chemicals and dried well. Once the jumbo reel is formed, its quality is checked and the sheets are further sent for cutting to form paper rolls.

Step 4: Producing final paper products –

The final outcome is the recycled paper which is now ready to use. The technical capabilities of recycled paper vary from virgin papers.

The printing performance also varies as compared to virgin fiber paper.

Once, the recycled paper is used and thrown away as a waste, the recycled paper completes its life cycle and the process is repeated from step 1.

These were the life cycles of virgin and recycled papers. If you have any queries, feel free to write to us at info@worldpapermill.com.

Join our group on Facebook and Linkedin to connect with the world’s smartest paper industry intellectuals and industry men.